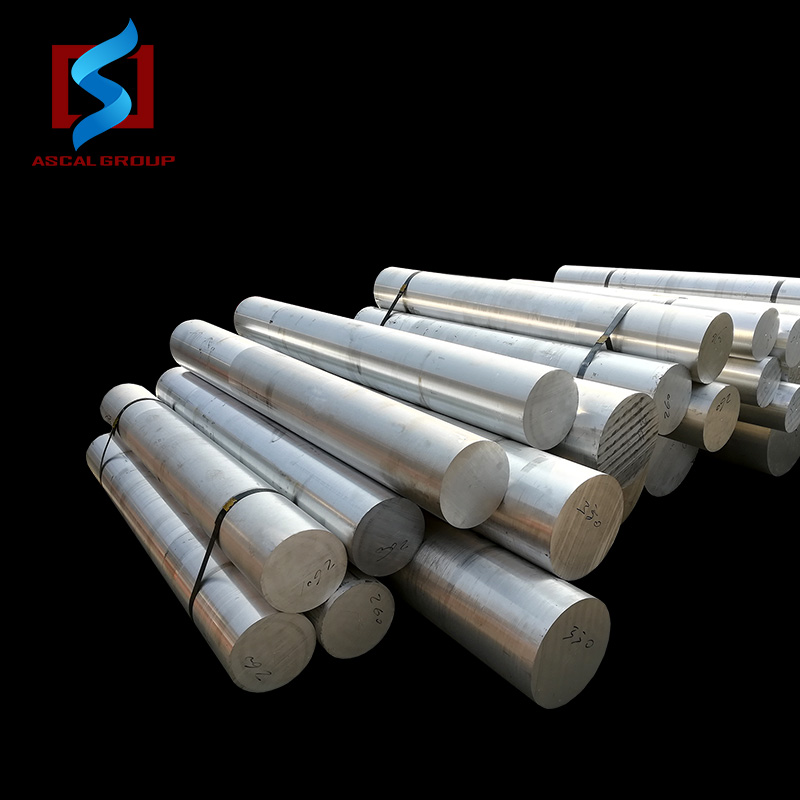

7075 Aluminum Round bar

Short description:

- TYPE: Extruded aluminium rod

- TEMPER: T4

- DIAMETER: 10-420mm (ready stock)

- LENGTH: 3000mm, Cut to short size ( φ≥ 30mm ),

- OTHERS: Material traceability, Mass-stock,Fast shippment

Product description:

Chemical composition of 7075 aluminum alloy

- Aluminum (Al): balance

- Silicon (Si): 0.4% max

- Ferrum (Fe): 0.5% max

- Copper (Cu): 1.2-2.0%

- Manganese (Mn): 0.3% max

- Magnesium (Mg): 2.1-2.9%

- Chromium (Cr): 0.18-0.28%

- Zinc (Zn): 5.1-6.1%

- Titanium (Ti): 0.2% max

- Other elements: Each 0.05% max, Total 0.15% max

Typical mechanical properties of 7075 T6 aluminum rod

For aluminum rod 7075 T6: φ25-100mm

- Tensile strength: ≥560 MPa

- Yield strength: ≥500 MPa

- Elongation: ≥7%

- Hardness (Brinell): 160 HB

(The values are typical or min values,for reference only.)

| PLACE OF ORIGIN | China |

|---|---|

| STANDARD | GB/T(default),ASTM,AMS,EN |

| MATERIAL CERTIFICATES | Material test report, and other certificates |

| SAMPLE | Support small sample (Chargeable) |

| PROCESSING SERVICE | Cutting, bending, CNC, anodizing, etc. |

| MOQ | Small MOQ with ready stock,even a piece. |

| LOGISTICS MODE | Express, by Land,by Air,by sea |

| SHIPPING PORT | Shanghai(default) |

| PAYMENT OPTIONS | TT, PayPal, L/C at sight, Pay on Alibaba |

| PACKAGING | Pallet(default), Wooden box(Chargeable) |

| LEAD TIME | 2-7 days for ready stock.Or mutual agreement |

| CUSTOMIZATION | Can be customized according to customer’s requirement |

| ABOUT PRICE | Fluctuate with aluminum prices & USD exchange rate |

what is 7075 Aluminum Round bar:

7075 Aluminum Round Bar: Superior Strength and Performance

The 7075 aluminum round bar is renowned for its exceptional strength and high-performance characteristics. This alloy is commonly used in aerospace, military, and sporting industries due to its impressive strength-to-weight ratio. It offers excellent corrosion resistance and has good machinability, making it suitable for a wide range of applications. The 7075 aluminum round bar is often utilized in structural components, aircraft fittings, missile parts, and high-stress applications where strength and reliability are crucial. Its superior mechanical properties, including high tensile strength and toughness, make it a top choice for demanding projects that require a lightweight yet durable material.