Why Is 7075 Aluminum Alloy a Top Choice for High-Strength Applications?

Why Is 7075 Aluminum Alloy a Top Choice for High-Strength Applications?

Hot keword :2024 5052 5083 6061 7075

The latest article

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

Why Is 7075 Aluminum Alloy a Top Choice for High-Strength Applications?

7075 aluminum alloy, part of the Al-Zn-Mg-Cu superhard alloy family, is a standout material for high-strength needs. It consists primarily of aluminum, augmented with zinc (5.1–6.1%), magnesium (2.1–2.9%), copper (1.2–2.0%), and trace amounts of manganese or chromium.

Its greatest strength lies in heat treatability. After solution treatment and artificial aging (e.g., the T6 temper), 7075 achieves a tensile strength of 500–570 MPa—rivaling some steels—while remaining far lighter. It also has excellent fatigue resistance, making it perfect for components under cyclic loads (e.g., aircraft landing gears).

Key applications across industries include:

- Aerospace: Aircraft structural parts (wing spars, fuselage frames) leverage its high strength-to-weight ratio.

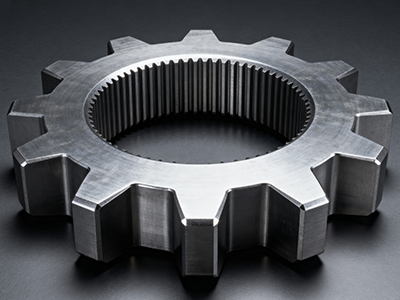

- Industrial: High-stress components like injection molds, heavy machinery gears, and oil drilling equipment depend on its durability.

- Sports: Premium bicycle frames, ski bindings, and climbing gear use 7075 for its lightweight toughness.

Different heat treatment “tempers” customize its properties:

- T6: Solution-treated + artificially aged to maximize strength (most common for critical parts).

- T651: Adds stretch straightening post-heat treatment to enhance dimensional stability (ideal for precision molds).

- T73: “Over-aged” to improve resistance to stress corrosion cracking (suited for marine/oilfield environments).

Notably, 7075’s natural corrosion resistance is weaker than pure aluminum or 5xxx series alloys. However, surface treatments like anodizing (creating a protective oxide layer) or powder coating effectively address this—while also adding aesthetic versatility.

When compared to other alloys:

- It outperforms 6061-T6 in strength (6061-T6 has ~310 MPa tensile strength) but falls short in weldability and corrosion resistance.

- Against 2024 aluminum (another aerospace alloy), 7075 offers higher static strength, while 2024 excels in fatigue crack growth resistance.

In short, 7075 aluminum alloy’s blend of high strength, heat treatability, adaptability to critical industries, and mitigatable corrosion issues makes it a top pick for demanding high-strength applications.