What Makes 1060 Aluminum Plate Stand Out in Conductivity?

What Makes 1060 Aluminum Plate Stand Out in Conductivity?

Hot keword :2024 5052 5083 6061 7075

The latest article

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

- 2024 (2A12) Aluminum Rods: The Aerospace-Grade Workhorse for High-Fatigue Precision Parts

- 2017 Aluminum Rods: Solving High-Stress Corrosion Pain Points for Precision Heavy-Duty Parts

- 2014 Aluminum Rods: Your Go-To for High-Strength, High-Temperature Precision Parts?

What Makes 1060 Aluminum Plate Stand Out in Conductivity?

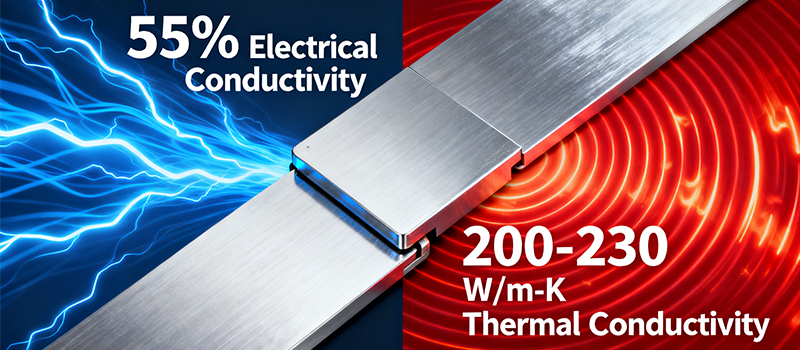

As a typical commercial pure aluminum, 1060 aluminum plate has a core advantage: 99.6% high aluminum purity. This nearly impurity-free composition directly gives it 55% electrical conductivity—a level far higher than most alloy aluminum materials. Moreover, strict control of trace impurities (Si≤0.25%, Cu≤0.05%) further avoids conductive performance loss, ensuring stable current transmission.

Core Properties of 1060 Aluminum Plate

1.Conductivity & Thermal Conductivity Correlation: While it excels in electrical conductivity, 1060 aluminum plate also has 200-230 W/m·K thermal conductivity. The positive connection between the two means it can simultaneously meet the needs of current transmission and heat transfer.

2.Excellent Processability: Despite its outstanding conductive performance, it maintains high formability—able to be processed into complex shapes via stamping and stretching. Even in H24 temper, it can achieve 90-degree bending without cracking, balancing performance and processing convenience.

3.Stable Performance Across Tempers: Its conductive property is hardly affected by temper. O temper (soft state) is flexible for forming, while H18 temper has higher hardness—both keep consistent conductivity, adapting to different usage scenarios.

Performance Optimization Tip

If corrosion resistance is required, 1060 aluminum plate can be treated with anodizing to form a dense protective film, which does not damage its conductive performance while extending service life.

We provide 1060 aluminum plate in full specifications (0.01mm-500mm) with internal stress relief treatment to prevent cutting deformation, fully matching the application needs of its core properties.