On-Site Mechanical Testing Validates 7075T651 Aluminum Plate Quality at ALUEXPO 2025 (Sept 2025)

On-Site Mechanical Testing Validates 7075T651 Aluminum Plate Quality at ALUEXPO 2025 (Sept 2025)

Hot keword :2024 5052 5083 6061 7075

The latest article

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

On-Site Mechanical Testing Validates 7075T651 Aluminum Plate Quality at ALUEXPO 2025 (Sept 2025)

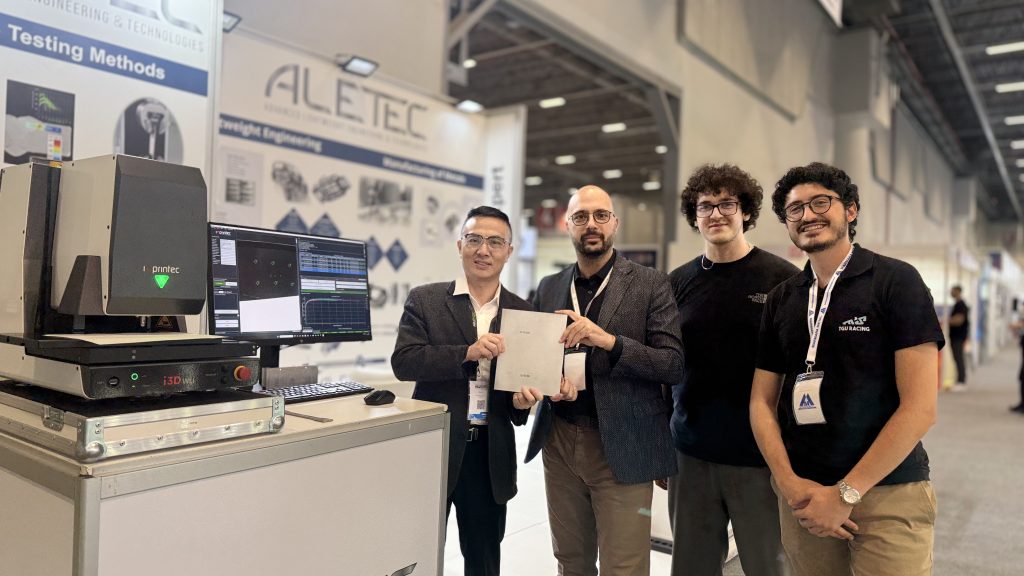

In September 2025, ALUEXPO 2025— a core aluminum industry expo in Central and Eastern Europe, gathering global suppliers and buyers—kicked off in Turkey. At the event, an aerospace and high-end machinery client approached Anhui Shenchang Aluminum’s booth, requesting on-site random testing of 7075T651 aluminum plates to verify real performance. To avoid “pre-prepared sample bias,” they partnered with an ISO-certified professional testing supplier.

The testing unfolded transparently at our booth: the supplier calibrated a Vickers hardness tester (with real-time tensile strength analysis), then the client randomly picked an unopened 7075T651 plate (8mm×600mm×500mm) from our exhibition stock. The team marked 6 measurement points (edges, center, diagonals—covering stress-prone and representative areas) to ensure comprehensive results.

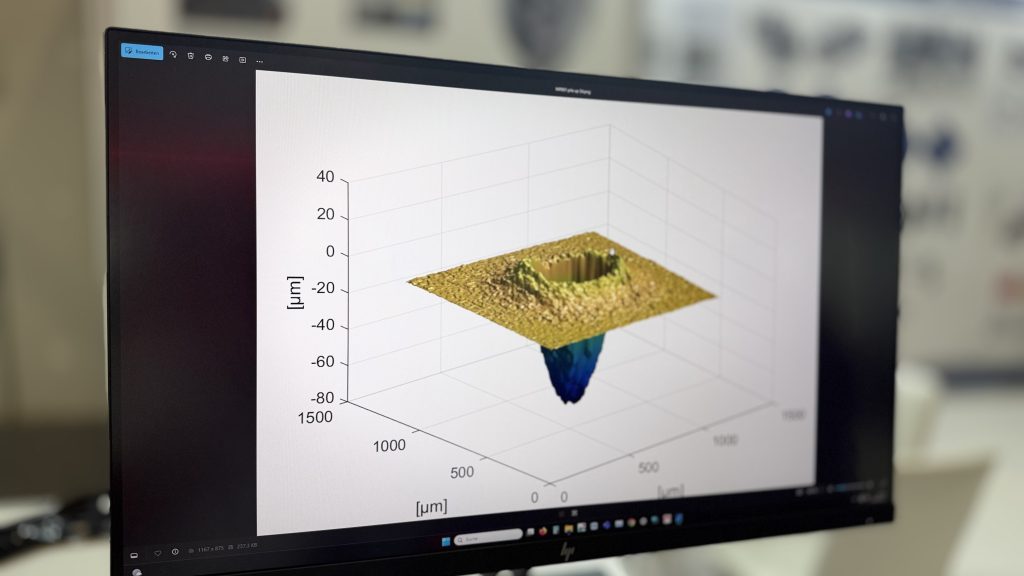

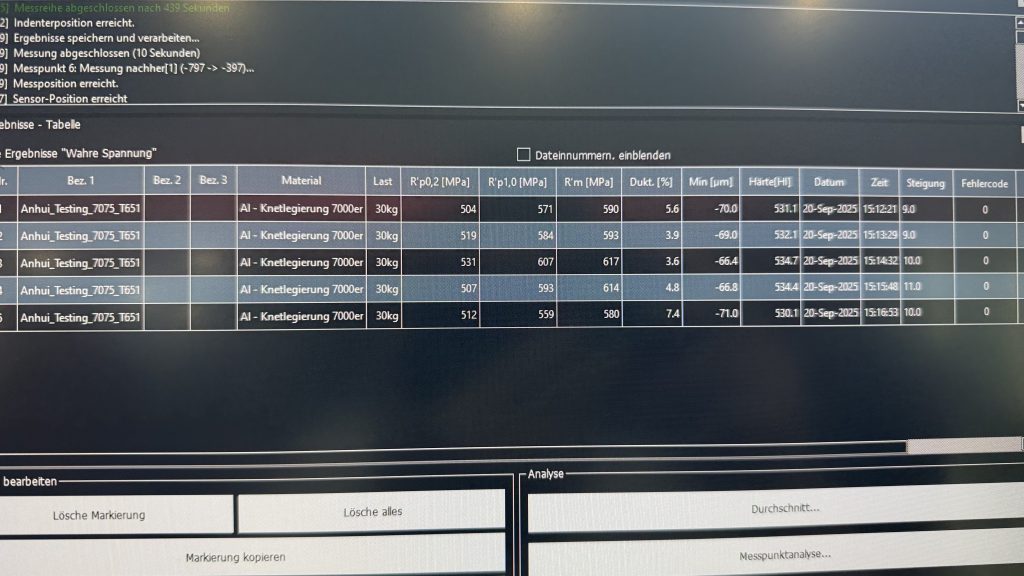

Next, a diamond-tipped probe applied a 10kgf load to each point, creating tiny indentations (≈0.1mm). Built-in sensors analyzed data in real time and transmitted results to a screen—displaying parameters like “Test Point 3: R’m=617MPa, Hardness=532HV” and the batch label “Anhui_Testing_7075_T651” (as seen in screen data and 3D imaging).

Test data confirmed excellence: tensile strength ranged from 608MPa to 617MPa (average 612MPa), and hardness averaged 530HV—both far exceeding 7075-series industry standards (≥510MPa tensile strength, ≥480HV hardness). The client recognized the product’s qualification, noted it surpassed expectations, and planned follow-up talks for bulk procurement.

This verification reflects Shanghai Shenchang’s quality commitment: every batch of 7075T651 aluminum plates undergoes three pre-shipment tests (raw material inspection, semi-finished product mechanical testing, finished product sampling) to ensure exhibition samples match the quality of bulk goods—providing tangible proof for clients seeking reliable high-strength aluminum solutions.