7A04 vs 7A09 Aluminum Plates: High-Strength Giants for Defense & Heavy-Duty Engineering

7A04 vs 7A09 Aluminum Plates: High-Strength Giants for Defense & Heavy-Duty Engineering

Hot keword :2024 5052 5083 6061 7075

The latest article

- For Extreme-Duty Scenarios: 5083 Aluminum Rods—The Unsung Hero of Harsh Environments

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

7A04 vs 7A09 Aluminum Plates: High-Strength Giants for Defense & Heavy-Duty Engineering

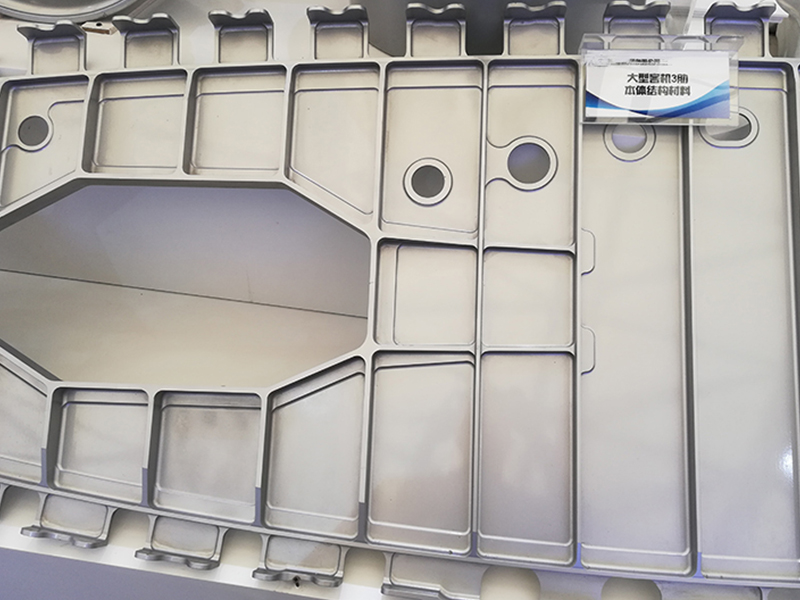

In the ultra-high strength Al-Zn-Mg-Cu alloy segment, 7A04 and 7A09 aluminum plates stand unrivaled. Both engineered for mission-critical scenarios requiring uncompromised strength, toughness and reliability, they dominate defense, aerospace and heavy machinery applications. While sharing the same alloy family and core advantages, subtle compositional differences tailor each to specific high-stress tasks—let’s break down their strengths, distinctions and ideal use cases.

First, their shared strengths make them indispensable. As heat-treatable alloys (optimized in T6/T651 tempers), 7A04 and 7A09 boast tensile strength over 500MPa, far outperforming 6xxx series. They offer excellent weldability (75%+ strength retention post TIG/MIG welding) and superior machinability for precision forming of complex structural parts. Both certified to GB/T 3880 and EN 485-2, they include manganese and chromium for enhanced corrosion resistance—critical for outdoor and marine environments.

shaping performance530-560MPin T6 temper—itstrait suitsWith,’s- components like riskThe key difference lies in zinc and copper content, shaping their performance priorities. 7A09, with higher zinc, achieves 530-560MPa tensile strength in T6 temper—its “strength champion” trait suits extreme load-bearing. With yield strength ≥460MPa and fatigue resistance 130MPa, it’s ideal for high-stress components like armored vehicle plates, helicopter rotor shafts and rocket launch pad structures. 7A04 (tensile strength 500-530MPa, yield strength ≥420MPa) prioritizes strength-toughness balance. Its higher fracture toughness

Real-world applications reflect these differences while overlapping in heavy-duty engineering. 7A09 excels in defense: main battle tank armor (withstanding armor-piercing projectiles) and military bridge girders (supporting 50+ ton loads). In aerospace, it’s selected for rocket engine brackets enduring launch vibration. 7A04 dominates aerospace components needing strength and ductility, like fighter jet wing ribs and commercial aircraft hydraulic parts. It also shines in marine engineering, where its toughness resists wave-induced cyclic stress on ship hulls and offshore platforms.

Our supply chain meets the strict demands of these high-strength alloys. We stock 8000 tons of 7A04 and 7A09 (T6/T651 tempers), covering 2-400mm thickness and up to 3000mm width. Every batch undergoes rigorous quality control, including AMS 2631 Level 2 ultrasonic flaw detection and certified mechanical test reports (tensile, fatigue, corrosion). For defense and aerospace projects, we offer custom heat treatment to fine-tune properties and precision cutting (±0.1mm tolerance). Standard specs ship in 5-10 days, with technical team support for alloy selection tailored to your project’s stress and environment needs.

Whether you need 7A09’s ultimate strength for defense hardware or 7A04’s balanced toughness for aerospace/marine components, both deliver critical-application reliability. Contact us today for free samples, detailed technical data sheets or a comparative test report to select the right high-strength aluminum plate for your project.