1060 Aluminum Rods: Pure Aluminum Workhorses for Cost-Effective Versatile Applications

1060 Aluminum Rods: Pure Aluminum Workhorses for Cost-Effective Versatile Applications

Hot keword :2024 5052 5083 6061 7075

The latest article

- For Extreme-Duty Scenarios: 5083 Aluminum Rods—The Unsung Hero of Harsh Environments

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

1060 Aluminum Rods: Pure Aluminum Workhorses for Cost-Effective Versatile Applications

In the pure aluminum (1000-series) category, 1060 aluminum rods stand as a cost-effective staple, crafted with 99.6% aluminum purity to deliver balanced performance for low-stress, high-reliability scenarios. As a non-heat-treatable alloy optimized in O, H112, and H24 tempers, it prioritizes conductivity, corrosion resistance, and formability over extreme strength—making it a go-to for electrical, architectural, and consumer goods industries worldwide. Let’s break down its core strengths, targeted applications, and supply advantages.

The core value of 1060 aluminum rods lies in their well-rounded fundamental properties. Electrically and thermally efficient, they offer 61-62% IACS conductivity and 210 W/m·K thermal conductivity, serving as an economical alternative to copper (48% lighter, cutting installation and transport costs). Corrosion resistance is inherent: a dense aluminum oxide passivation layer forms naturally, protecting against atmospheric moisture, mild chemicals, and outdoor exposure—ideal for food processing equipment, marine trim, and architectural fixtures.

Formability is where 1060 truly excels. Its exceptional ductility (over 20% elongation in O temper, 3-5% in H24) enables seamless deep drawing, stamping, bending, and spinning without cracking, while TIG/MIG welding retains over 90% joint strength—perfect for high-volume fabrication. Mechanical performance varies by temper: O temper delivers 70-90MPa tensile strength and ≥35MPa yield strength for maximum formability, while H24 temper boosts tensile strength to 110-136MPa and yield strength to ≥95MPa for structural rigidity, all adhering to GB/T 3196 and ASTM B211 standards.

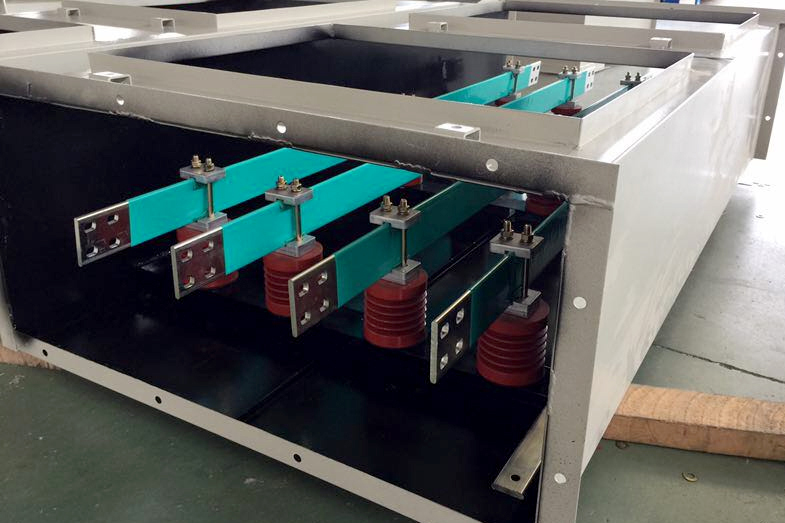

Real-world applications span diverse low-stress scenarios. In electrical and electronics, 1060 rods are used for power busbars, transformer windings, battery terminals, and LED heat sinks—marrying conductivity with lightweight design. For architecture and decor, O-temper rods shape into custom trim, signage, and ceiling panels, while H24 temper suits rigid window frames and structural trim. Consumer goods benefit from its non-toxicity and formability, with uses in deep-drawn cookware, chemical tanks, and reflectors.

Even precision manufacturing leverages small-diameter 1060 rods (3-50mm) for Swiss-type CNC machining of sensor housings and connectors, thanks to straightness <0.2mm/m that ensures stable high-speed turning. The transportation sector also uses it for lightweight trim, HVAC ducting, and trailer panels, cutting vehicle weight and fuel consumption without compromising fabrication flexibility.Our supply chain meets the demands of high-volume and precision production, with 5000 tons of 1060 aluminum rods in stock—covering O, H112, and H24 tempers, diameters 3-200mm, lengths up to 6m, and round, square, hexagonal profiles. Every batch undergoes ultrasonic flaw detection (for critical electrical parts) and comes with certified mechanical test reports, verifying tensile