Why Can Aluminum Be Light Yet Strong?

Why Can Aluminum Be Light Yet Strong?

Hot keword :2024 5052 5083 6061 7075

The latest article

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

Why Can Aluminum Be Light Yet Strong?

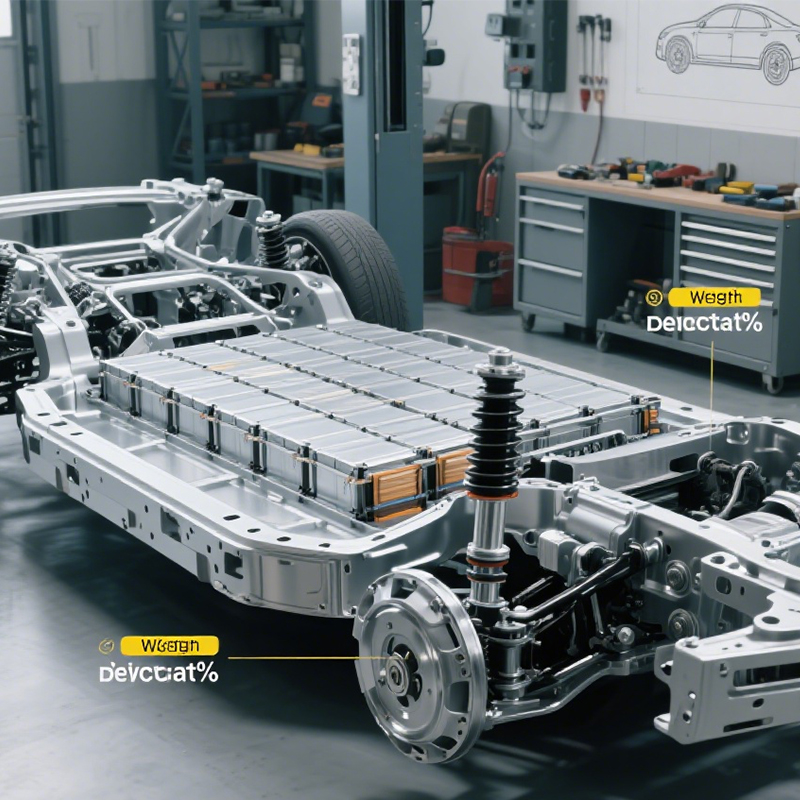

In the field of materials, “lightweight” and “durability” are often mutually exclusive, but aluminum breaks this norm, standing out as a material that excels in both.

By nature, aluminum has a density of roughly one-third that of steel, endowing it with an inherent lightweight quality. Through alloying technology, adding elements like copper, magnesium, and manganese to aluminum significantly enhances its strength—some aluminum alloys even rival steel in terms of strength. This unique combination of being “lightweight” yet “remarkably tough” allows aluminum to shine in various fields.

In the aerospace sector, aluminum’s lightweight property helps reduce fuel consumption for aircraft while meeting the strict structural strength requirements of airframes. In automotive manufacturing, using aluminum components lowers vehicle weight, improving range capability and handling. Even the casings of portable electronic devices rely on aluminum to balance sleek, thin designs with impact resistance.

It is this distinctive balance of “lightness and strength” that makes aluminum an ideal choice for efficiency and energy savings in modern industry, continuously driving lightweight innovation across sectors.