7075 Aluminum Plate: The Legacy High-Strength Alloy for Precision & Performance

7075 Aluminum Plate: The Legacy High-Strength Alloy for Precision & Performance

Hot keword :2024 5052 5083 6061 7075

The latest article

- For Extreme-Duty Scenarios: 5083 Aluminum Rods—The Unsung Hero of Harsh Environments

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

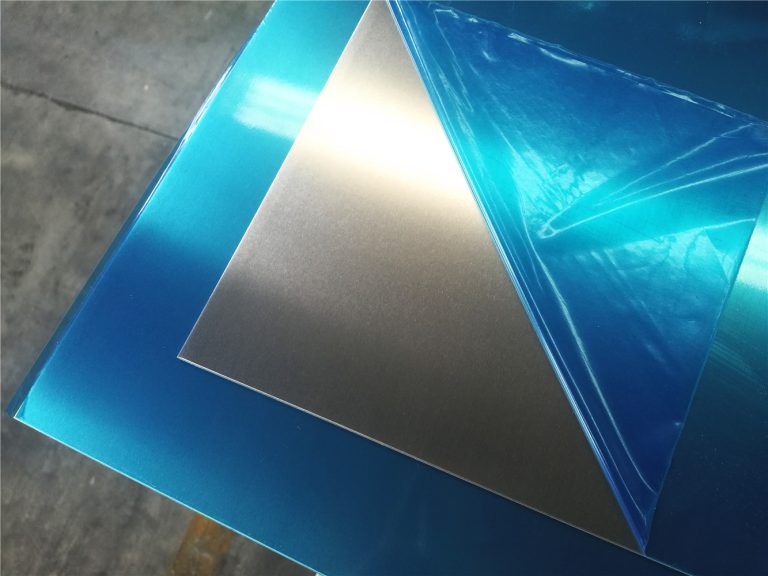

7075 Aluminum Plate: The Legacy High-Strength Alloy for Precision & Performance

In the world of ultra-high strength aluminum, 7075 stands as a time-tested legacy—an Al-Zn-Mg-Cu alloy renowned for its uncompromising tensile strength and precision, making it a staple in aerospace, defense, and high-end manufacturing for decades. Though newer alloys like 7050 have addressed some of its limitations, 7075 remains the go-to for applications where maximum strength takes priority.

Core Strengths of 7075

As a heat-treatable alloy (optimized in T6/T651 tempers), 7075 delivers industry-leading tensile strength: up to 572MPa in T6 temper, with yield strength ≥503MPa—far exceeding most 6xxx or even 7xxx series alternatives. It offers excellent machinability, enabling tight tolerances (±0.05mm) for precision components like aircraft fasteners or mold cores. Certified to ASTM B209 and AMS 4049, it balances strength with moderate corrosion resistance (enhanced by manganese additions), suitable for indoor or controlled-environment high-stress tasks.

Key Applications

7075 shines in scenarios where strength is non-negotiable:

Aerospace: Aircraft wing ribs, landing gear components, and satellite structural frames (where its high strength-to-weight ratio cuts launch mass).

Defense: Military firearm components and armor plating (withstanding impact forces without excessive bulk).

Manufacturing: High-precision mold inserts and CNC-machined tooling (retaining shape under repeated stress).

Limitations to Note

While strong, 7075 has tradeoffs: its stress corrosion resistance is lower than 7050 (surviving ~500 hours of salt-spray testing), and it loses ~20% strength in thick plates (≥100mm) due to uneven hardening. These drawbacks make it less ideal for marine or outdoor long-term use—but unbeatable for controlled-environment high-strength needs.

Supply Assurance

We stock 6000 tons of 7075 (T6/T651 tempers), covering 1-300mm thickness and up to 2800mm width. Every batch includes ultrasonic flaw detection (AMS 2631 Level 2) and mechanical test reports. Standard specs ship in 3-7 days, with custom heat treatment available to fine-tune hardness for specific tooling or aerospace needs.

7075 isn’t the most all-rounded 7xxx alloy, but it’s the strongest—making it irreplaceable for precision high-stress tasks. Contact us for free samples or technical data sheets to see if 7075 fits your project.