2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

Hot keword :2024 5052 5083 6061 7075

The latest article

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

- 2024 (2A12) Aluminum Rods: The Aerospace-Grade Workhorse for High-Fatigue Precision Parts

- 2017 Aluminum Rods: Solving High-Stress Corrosion Pain Points for Precision Heavy-Duty Parts

- 2014 Aluminum Rods: Your Go-To for High-Strength, High-Temperature Precision Parts?

2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

In industrial scenarios requiring hot forging of complex components and long-term operation at moderate temperatures, ordinary aluminum alloys often suffer from cracking during forging or performance attenuation under heat. 2A50 and 2A70 aluminum rods—twin stars of the 2000-series Al-Cu-Mg-Si alloys—are engineered for this exact demand. Optimized for heat resistance and hot work ability, they deliver stable medium-high strength in high-temperature environments, making them the preferred choice for forged parts in automotive, machinery, and power equipment sectors.

The core advantage of 2A50/2A70 lies in their tailored alloy compositions and excellent heat-resistant forging performance, with subtle differences that suit distinct sub-scenarios. Both alloys are heat-treatable (optimized in T6 temper) and comply with GB/T 3196 standards:

2A50: Blended with moderate silicon content, it boasts superior castability and hot forging fluidity, enabling seamless forming of intricate shapes like curved lever arms and hollow shafts. In T6 temper, it achieves tensile strength of 350-380MPa and yield strength ≥280MPa, retaining 75% of its room-temperature strength at 180℃.

2A70: Fortified with higher magnesium additions, it elevates high-temperature stability to a new level—retaining 80% of room-temperature strength at 200℃, with tensile strength reaching 370-400MPa in T6 temper. Its enhanced creep resistance makes it ideal for components under sustained thermal stress.

Beyond heat resistance and forging performance, both alloys offer reliable processability for post-forging finishing: good machinability enables tight dimensional tolerances (±0.03mm) for precision parts, while TIG welding with matching fillers retains 60-65% joint strength—suitable for on-site assembly of large forged components. A key note: their corrosion resistance is moderate; chemical conversion coating or high-temperature paint is recommended for outdoor or humid working environments.

Target application scenarios are divided based on their subtle performance differences, covering medium-high stress heat-exposed components:

2A50 Applications: Automotive engine connecting rod blanks, agricultural machinery gearbox shift forks, and hydraulic cylinder piston forgings—leveraging its excellent forging fluidity for complex structural parts.

2A70 Applications: Internal combustion engine piston pins, power plant high-temperature valve stems, and heavy machinery forging die accessories—relying on its superior high-temperature creep resistance for long-term stable operation.

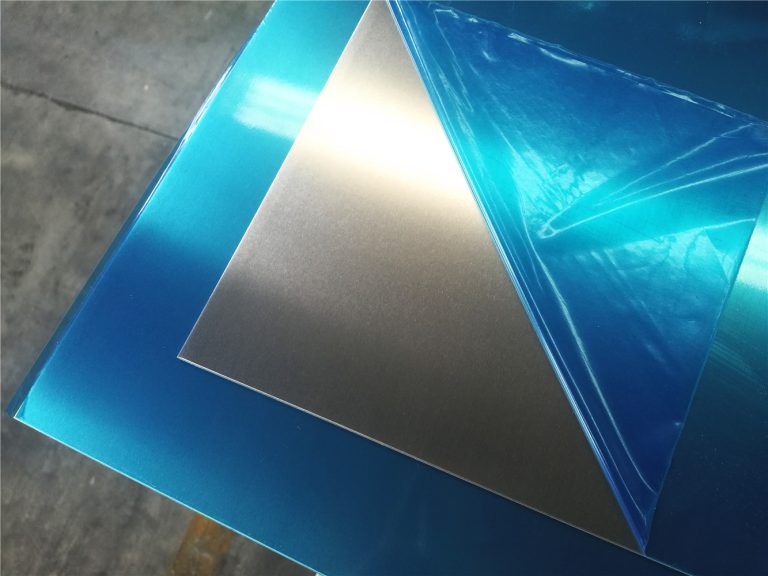

Our supply chain is optimized for forging-oriented batch demand: 3000 tons of 2A50/2A70 aluminum rods in stock (T6 temper), covering diameters 8-200mm and lengths up to 6m (round/square profiles available). Every batch undergoes strict hot forging performance testing and ultrasonic flaw detection (Level II), ensuring no internal defects cause forging cracking. We offer value-added services including custom pre-forging heat treatment, precision cutting (±0.05mm tolerance), and surface sandblasting, with standard specifications shipping in 3-6 days.

If your project requires heat-resistant aluminum rods for medium-high stress forged components, 2A50/2A70 are the targeted solutions. Contact us for free forging test samples and detailed technical data sheets to optimize your forging process.