4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

Hot keword :2024 5052 5083 6061 7075

The latest article

- Need Aluminum Rods for Harsh Corrosion? 5056 Delivers Strength Without Compromise

- Which Aluminum Rod is Perfect for Corrosion-Resistant & Easy-Processing Industrial Parts? 5052 Has the Solution

- 4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

- 3003 Aluminum Rods: The Corrosion-Resistant All-Rounder for Light Industrial Applications

- 2A50/2A70 Aluminum Rods: Heat-Resistant Forging Specialists for Medium-High Stress Industrial Components

- 2A11 Aluminum Rods: Cost-Effective Medium-Strength Solution for General Industrial Precision Parts

4032 Aluminum Rods: The High-Silicon Hardness Champion for High-Wear Engine & Mold Components

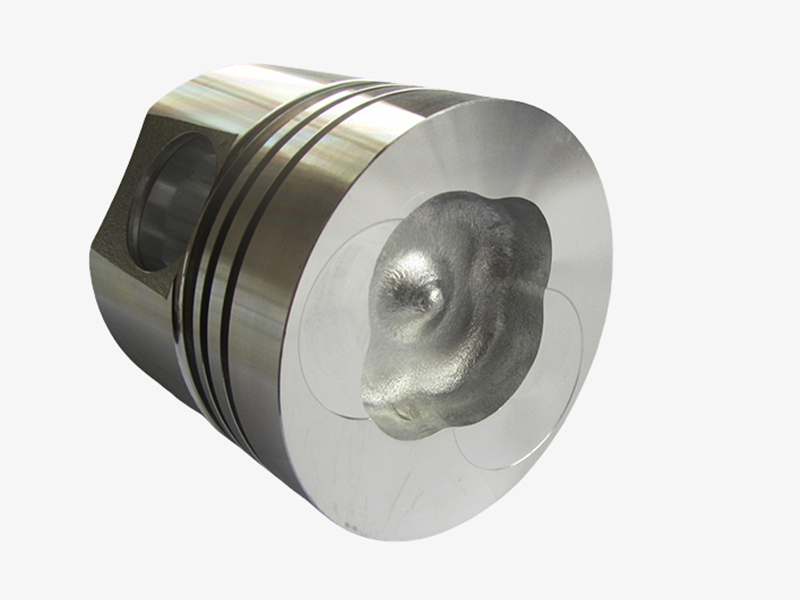

For industrial components under extreme wear, high-temperature friction and repeated mechanical impact—such as engine pistons, precision mold cores and high-speed transmission parts—ordinary aluminum alloys deform and degrade quickly, affecting equipment efficiency and service life. 4032 aluminum rods, a high-performance 4000-series Al-Si-Mg-Cu alloy with 11.0-13.0% silicon, are tailored for this demand. With excellent hardness, wear resistance and high-temperature stability, it’s the preferred choice for high-wear precision parts in automotive, mold and heavy mechanical industries.

4032’s core strength comes from its high-silicon composition and optimized T6 heat treatment. High silicon forms uniformly distributed hard particles, acting as wear-resistant reinforcements, with Brinell hardness 120-140HB (surpassing 2000/3000-series alloys). In T6 temper, tensile strength is 300-330MPa, yield strength ≥240MPa, and it retains 85% hardness at 250℃, ensuring stable operation in high-temperature environments like engine cylinder bores. Compliant with GB/T 3196 and ASTM B211, its 2.68g/cm³ density balances wear resistance and lightweight design for high-speed rotating components.

4032 has good casting and forging fluidity, facilitating seamless forming of complex parts like piston crowns and mold inserts. It offers reliable machinability (±0.03mm tolerance for precision grinding/milling) and weldability (60-65% joint strength with high-silicon fillers), suitable for on-site assembly of large wear-resistant components. Note: Corrosion resistance is moderate; hard anodizing is recommended for outdoor/humid environments to enhance protection and extend service life.

Key applications (high-wear, high-temperature): Automotive (engine pistons, valve lifters) – withstands friction and thermal stress during long-term operation; Precision Mold (wear-resistant cores, injection screw tips) – resists impact/abrasion to extend service life; Mechanical Transmission (gear shafts, bearing bushes) – ensures stable power transmission under heavy load; Aerospace Auxiliary Parts (engine oil pump components) – balances lightweight design and extreme wear resistance.

We have 2800 tons of 4032 rods in stock (T6 temper), covering diameters 8-200mm and lengths up to 6m (round/square profiles for diverse needs). Every batch undergoes strict quality inspections (wear resistance, hardness, Level II ultrasonic flaw detection) to avoid internal defects. We provide value-added services: custom pre-forging heat treatment, precision grinding (±0.02mm) and hard anodizing. Standard specs ship in 4-7 days, with technical support for parameter optimization in high-wear scenarios.

If your project needs aluminum rods with exceptional wear resistance, hardness and high-temperature stability for high-wear precision components, 4032 is the professional choice. Contact us for free wear resistance samples and technical data sheets to optimize your production process.